Achieving Smooth Internal Bends Through Better Tube Support

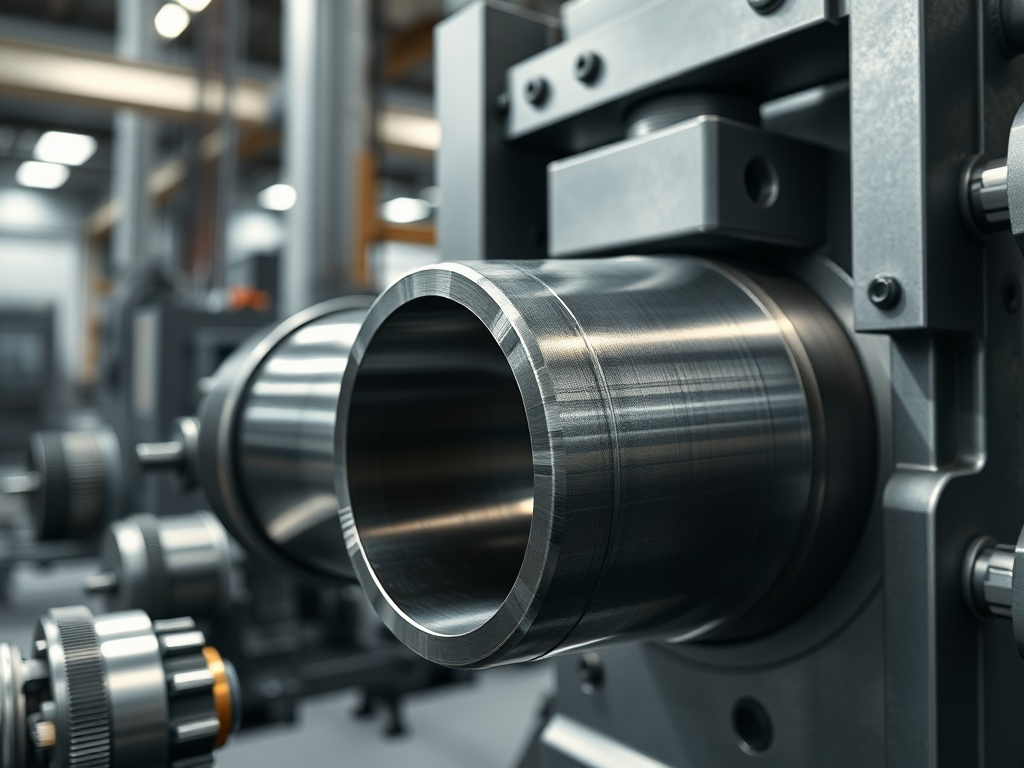

Tube bending sits at the centre of many manufacturing processes, shaping components used in transport, energy systems, and structural assemblies. The quality of each bend affects strength, fit, and long term performance, particularly where precision is required. Using a mandrel bender allows manufacturers to maintain internal shape during forming, producing cleaner bends without distortion or collapse.

As designs become more compact and expectations around accuracy increase, controlling what happens inside the tube during bending has become just as important as shaping the exterior. Internal support provides that control, helping components meet both functional and visual requirements.

How Internal Support Improves Bend Accuracy

When a tube is bent without internal reinforcement, material on the inner radius compresses while the outer wall stretches. This imbalance often leads to ovalisation, wrinkling, or flattening, especially when working with thin walls or tight curves.

Internal support stabilises the tube throughout the forming process. By supporting the inner diameter, the mandrel allows material to flow evenly, resulting in smoother curves and more predictable dimensions. This consistency becomes increasingly valuable as tolerances tighten.

Making Complex Bends More Achievable

Many modern designs require bends that leave little margin for error. Space constraints, airflow requirements, and aesthetic considerations often demand tighter radii and more intricate shapes than traditional bending methods can reliably deliver.

With internal support in place, these challenges become manageable. Tubes can be formed accurately without compromising wall thickness, which is particularly important in applications where internal dimensions affect performance, such as fluid transfer or exhaust systems.

Keeping Production Output Consistent

Inconsistent bending creates problems further down the production line. Components that vary even slightly may not fit during assembly, leading to delays and additional inspection time. Supported bending techniques help prevent this by producing repeatable results across entire batches.

Once parameters are set, manufacturers can run longer production cycles with confidence. This repeatability simplifies quality checks and reduces the likelihood of rejected parts, helping teams maintain steady throughput.

Cutting Down Waste and Rework

Poor bend quality often leads to scrapped material or time consuming rework. Without internal support, small deviations can render a component unusable, particularly in high specification projects.

By maintaining internal shape during bending, supported systems reduce the risk of defects. This leads to better material use, fewer rejected parts, and more predictable production schedules, all of which support cost control.

Supporting Strength and Long Term Performance

Bent tubes are frequently used in applications where durability matters. Structural frames, pressure systems, and safety related components all depend on accurate forming to perform as intended.

Maintaining internal consistency during bending helps preserve strength and reduces stress points. This gives manufacturers greater confidence that finished components will perform reliably under load and over time.